It is how closely the actual cycle matches the theoretical Otto cycle. The presence of the burnt out gases would reduce the fresh charge in the combustion chamber and hence its capacity to produce energy.Ĭombustion quality is a concept given by T H Ma. Increase of residual gases in the combustion chamber would reduce the flame speed. Thus flame speed increases with increase in compression ratio. These two conditions favour the flame speed. The engine speed higher would be the turbulence and greater would be the flame speed.Īt high compression ratios both pressure and temperature of the air fuel mixture would increase.

In small size engines the flame has to travel less distance and hence it takes less time for the flame travel.įlame speed increases almost linearly with engine speed. At higher loads with more throttling the working mixture is suited for combustion and hence smooth operation is obtained. There is increase in flame speed with increase in engine load. With increase in intake temperature and pressure the flame speed increases. We can broadly have two types of combustion in SI engines- Normal Combustion and Abnormal Combustion.Įffect of Engine Variables on Ignition Lag in SI Engines: With the burning of adjacent layers, the flame travels the entire cylinder.

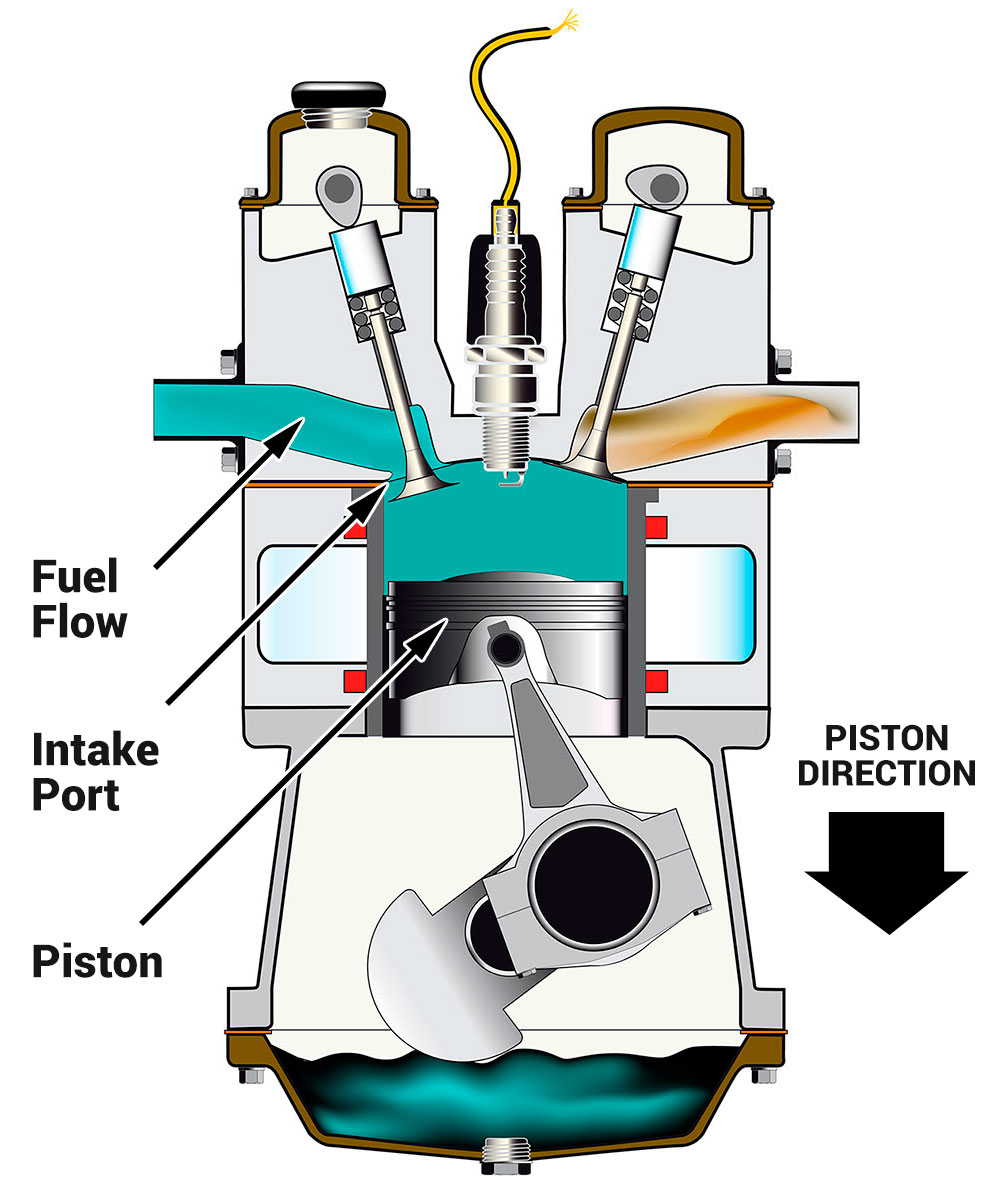

The molecules in and around the spark plug starts burning, when an intense and high temperature spark is generated between the electrodes of homogenous mixture of vaporised fuel, air and residual gases.Īs the charge near the spark burns, a flame is formed whose speed is extremely low because the reaction zone is yet to be established and heat loss is high since walls are cold. The flame speed would depend on the temperature of the flame front and to some extent on the temperature and density of the air fuel mixture.

The combustion spreads from around the spark plug and spreads rapidly across the combustible mixture inside the chamber. The spark may have temperature as high as 10,000☌. Towards the end of the compression stroke the spark plug gives out high temperature spark to initiate the ignition process. In SI engines the combustion chambers have homogeneous air fuel mixture that is compressed after induction stroke.

0 kommentar(er)

0 kommentar(er)